Transformer windings are formed with precision around a large spool, with each number of turns dependent on the voltage ratio of the transformer being constructed. Photo: Siemens

In industrial installations, transformers are mainly used to step down a higher distribution level voltage to a lower utilization level. They are vital links in electrical power systems and are among the most reliable components in the system.

Transformers can be divided into two general categories according to their insulating medium and construction: liquid filled and dry type. Each has several variations and each requires different maintenance techniques.

Field tests are conducted to verify that installed equipment has not been damaged and is ready for energizing. Photo: IAEA Imagebank (Flickr CC).

Testing electrical equipment in the field is the best way to assure that it will perform its design functions safely and adequately.

While the manufacturer conducts electrical tests on equipment before it leaves the factory, these tests mean nothing once the equipment is exposed to the elements and rough handling involved with transportation and installation.

The main objective of a battery system is to provide standby and emergency power to critical equipment during an AC outage. Photo: Paul Chernlkhowsky (Flickr CC).jpg

Batteries are complex chemical mechanisms. They are comprised of a number of cells connected in a series path. If any one component fails the entire series connection fails.

The main objective of a battery system is to provide standby and emergency power to critical equipment during an AC outage. A good battery maintenance program may prevent, or at least, reduce the costs and damage to critical equipment.

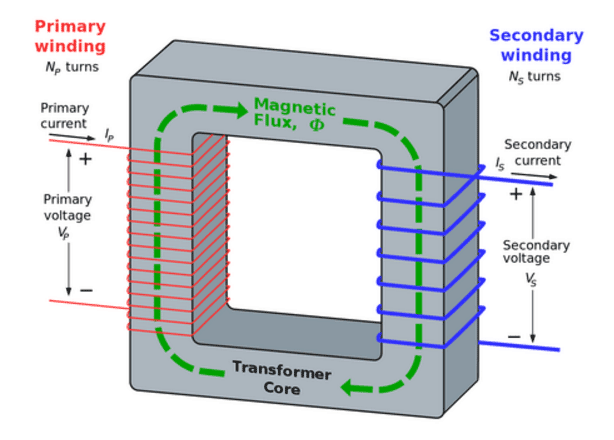

When the primary winding of a transformer is energized with an alternating current (AC), alternating magnetic lines of force, called "flux," circulates through the core, establishing a magnetic field. Photo: Quora

Transformers efficiently transfer electrical energy from one circuit to another by means of magnetic induction. Each phase of a transformer is composed of two separate coil windings wound on a common core.

The transformer primary winding receives electrical energy from the power source. When the primary winding is energized with an alternating current (AC), alternating magnetic lines of force, called "flux," circulates through the core, establishing a magnetic field.

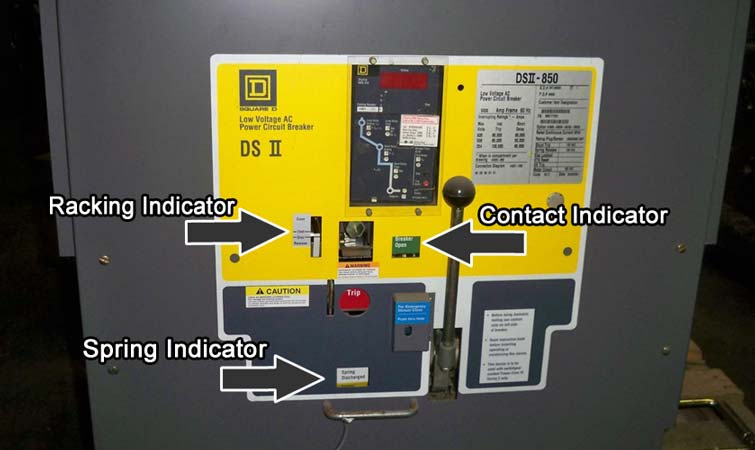

There are three main indications associated with draw-out breakers that every test technician should know. Photo: EMSCO.

Draw out circuit breakers are equipped with three important flags that indicate the operating state of an electrical circuit.

Thorough knowledge of these indications and their associated assembly is critical in order to correctly operate and maintain circuit breakers.

Batteries contain volatile, and therefore potentially, hazardous materials which can cause burns and other serious injuries. Photo Credit: Wikimedia

Batteries are used extensively across the power grid to ensure that critical electrical equipment is always on.

Without battery backup, many of the services that we take for granted would fail leading to incalculable damage.

The case of the transformer should always be regarded as energized until the tank ground connection is inspected and found to be adequate (OSHA 29 CFR 1910.269(l)(11)). Photo Credit: Paul Chernlkhowsky (Flickr CC)

Transformers are vital links in electrical power distribution and are among the most reliable components in the system.

Because a transformer failure is usually of a very serious nature, requiring extensive repair and long downtime, regular preventive maintenance procedures are the best assurance of continued high reliability.

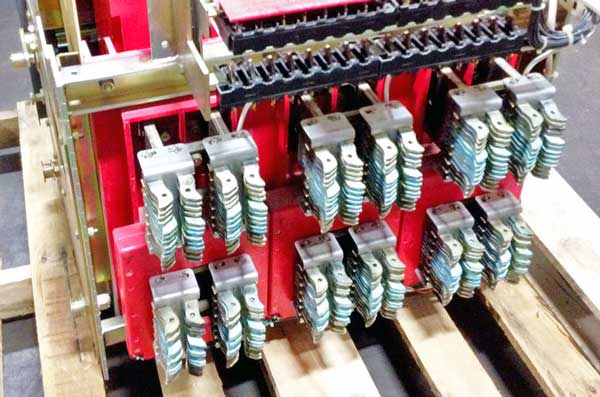

If the primary stabs of a circuit breaker haven't been lubricated, it increases the force required to connect them to a power source.

Lack of lubrication is the number one problem test technicians run into when servicing circuit breakers in the field. All circuit breakers have lubricant applied to them at the factory, but over the course of time this lubricant dries out, leaving metal-to-metal wear in its place.

The result is a circuit breaker that won't open, won't close, or operates slower than usual.

Sharpen your skills with our collection of quizzes on electrical safety, maintenance & testing of electrical equipment and industry standards.

Tech Quiz Study Guide